Steel Wire Rod: What Is It and What Is It Used For?

Steel wire rod is one of the most highly valued materials in the construction industry. In this article,We will briefly explain how it is made, what its properties are and what characteristics give it this versatility.

What Is Steel Wire Rod?

It is a material that is produced by mixing scrap, sponge iron and alloying elements. These raw materials then go through a hot rolling process that prepares the wire rod for use in the manufacture of parts such as welded mesh, stirrups, barbed wire, sieves, armour, or springs, to name just a few.

Likewise, wire rods are widely used in construction projects for making stirrups, assembling reinforcement structures with rods, and tying bundles of rods.

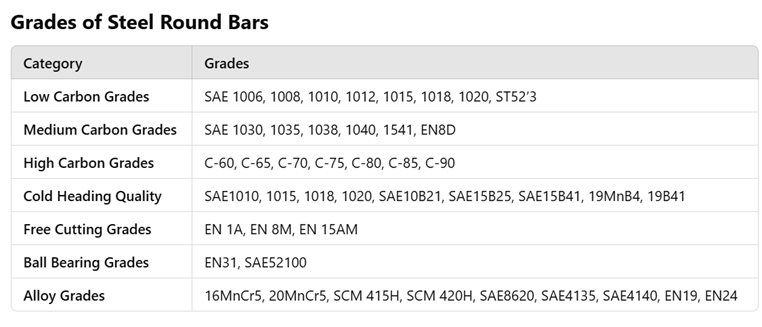

We at Prime Steel manufacture various grades of wire rods, such as low carbon, cold heading (CHQ), medium carbon, high carbon, and other alloy grades that include free-cutting steel, ball-bearing steel, and any other grades required by our customers.

These wire rods can be used in multiple engineering industries such as hand tools, automotive, cycles, fasteners, cables, nails and screws.

Types of Steel in Wire Rod Manufacturing

Depending on the type of treatment they receive and the function that the parts or structural elements are to perform, wire rod is only offered in one type on the market: hot rolled.

Wire rod is manufactured using a process in which billets are used and then drawn. First, a hot rolling treatment is carried out, which gives it its characteristic strength, malleability and smooth surface qualities that allow it to undergo other industrial processes, such as the manufacture of wires that are subsequently cold rolled.

Its most important quality, as we have said, is its resistance which allows it to withstand mechanical stress in construction projects or act as a reinforcing element in small sections that require a complement to ensure installation.

Hence the importance of these products complying with current regulations for the steel industry.

Wire Rod: Measurements and Dimensions

We offer this material in different grades, including high, medium and low carbon wire rods. In relation to measurements, wire rods can be found in different diameters, which vary according to specific needs. At Prime Steel, we manufacture wire rods ranging from 5.5 mm to 32 mm.

Main Applications

Steel wire rod is a key material in the construction industry but it is also widely used in many other industries, including security, hardware, and agriculture where it has a large number of applications, especially as a raw material in the production of fences and mesh.

Construction Industry

In this industry, steel wire rod is used as a complement to manufacture corrugated steel structures (rods) or permanent structural elements. It is used to make stirrups where castles and chains are placed.

Manufacturing Industry

Steel wire rod is used in the production of nails and woven wire, as well as reinforcing mesh, annealed wire, and barbed or galvanized wire as well as elements for foundations and other essential components for the manufacture of various products.

Agricultural Sector

It is also a highly valuable material in the agricultural industry, as it is used to make fencing wires and other essential elements for working in the fields.

Other Common Features and Applications:

- Drawing (Forming) Quality: Ideal for general wire drawing processes and producing items like nails, screws, and standard wire products.

- Mesh Quality: Designed for fabricating wire meshes used in construction, fencing, and protective barriers.

- Cold-Heading Quality: Used to manufacture fasteners such as bolts and nuts through cold-forming processes.

- Electrode Quality: Used in the production of welding electrodes and wires. Made ensuring consistent electrical conductivity and performance.

Specialized Qualities and Their Uses:

- Chain Quality: Employed in producing various types of chains, offering high tensile strength and durability.

- Tire Cord Quality: Used in manufacturing tire reinforcement materials. Provide essential strength and flexibility.

- Scrapless Quality: Designed to minimize waste during processing.

- Fine Wire Quality: Suitable for drawing into fine wires for applications in electronics and precision instruments.

- Lead Quality: Incorporated in applications requiring enhanced machinability, often alloyed with lead.

- Music Spring Quality: Used inthe production of high-quality springs. For musical instruments that require precise performance.

- Concrete Reinforcement Quality: Used in reinforced concrete structures to enhance tensile strength and structural integrity.

- Industrial and Standard Quality: General-purpose wire rods suitable for a wide range of industrial applications.

- Thermal Quality: Designed for applications involving elevated temperatures that require strength and stability.

- Cold Finishing Quality: Ideal for processes requiring further cold working, such as cold drawing to achieve specific dimensions and surface finishes.

- Welding Quality: Specially produced for manufacturing welding wires and electrodes, ensuring optimal weld quality and performance.

When it comes to reliability, precision, and quality, Prime Steels stands at the forefront of steel wire rod manufacturing. Whether you’re in construction, manufacturing, or agriculture, our expertly crafted wire rods are designed to meet your toughest demands with strength and precision.Connect with Prime Steels today to get the exact material you need for your project.